Geotechnical Construction / Mining

AERLITE™ foam liquid concentrate is a hybrid formula that uses the performance of the protein-based products and combines them with the agility of the straight synthetic products. The AERLITE family of foaming agents, most commonly used in geotechnical applications, produces a lightweight cellular concrete when combined with a cement slurry.

AERLITE™ foam liquid concentrate is a hybrid formula that uses the performance of the protein-based products and combines them with the agility of the straight synthetic products. The AERLITE family of foaming agents, most commonly used in geotechnical applications, produces a lightweight cellular concrete when combined with a cement slurry.

AERLITE HCR™ is a synthetic foaming agent designed for high carbon resistance applications, which allows it to be used with mix designs that incorporate high carbon quality fly ashes. Aerlite HCR foam is formulated to remain stable even when used with high carbon Class F and Class C fly ashes. Each project should be laboratory tested with local materials to confirm expected compatibilities.

AERLITE-iX™ is the new generation of foam technology. The fully synthetic foam liquid concentrate in the AERLITE family of foaming agents is engineered to produce a more flexible bubble structure which allows for extended pumping distances and increased lift heights. AERLITE-iX is predominantly used in geotechnical applications and can meet challenges other products cannot.

AERLITE-iX™ is the new generation of foam technology. The fully synthetic foam liquid concentrate in the AERLITE family of foaming agents is engineered to produce a more flexible bubble structure which allows for extended pumping distances and increased lift heights. AERLITE-iX is predominantly used in geotechnical applications and can meet challenges other products cannot.

AERLITE-R™ is a fully synthetic foam liquid concentrate that is specifically formulated for annular fills. It is designed to be highly flowable for pumping long distance in tight tolerances. As with the entire Aerix Industries family of foaming agents, Aerlite-R conforms with standard specifications of ASTM C869 when tested in accordance with ASTM C796.

Roofing / Manufacturing

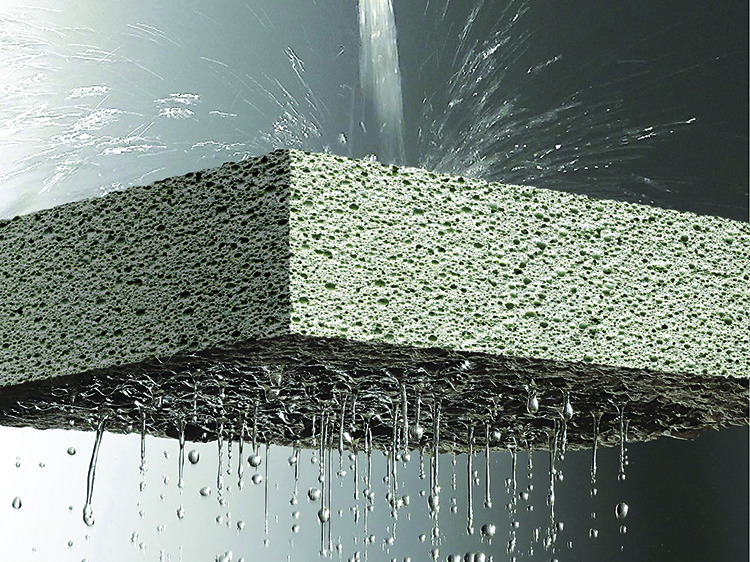

MEARLCRETE™ is a traditional protein-based foam liquid concentrate using a formula that has been proven since the 1940’s. Protein formulas produce a rigid bubble structure which allows for a stable foam for the use in predominately above grade construction applications. MEARLCRETE has a UL rating and appropriate ESR-2748 report, which allows for flexibility in the roofing industry.

MEARLCRETE™ is a traditional protein-based foam liquid concentrate using a formula that has been proven since the 1940’s. Protein formulas produce a rigid bubble structure which allows for a stable foam for the use in predominately above grade construction applications. MEARLCRETE has a UL rating and appropriate ESR-2748 report, which allows for flexibility in the roofing industry.

Ready Mix

AERFLOW is a synthetic foam liquid concentrate formulated for the production of controlled low strength material (CLSM), more commonly known as flowable fill or flow fill. 3 oz of AERFLOW per cubic yard of finished concrete will increase the slump of the initial mix from 1.5 inches to 7-9 inches. Yields can be increased by 20-25%.

AERFLOW is a synthetic foam liquid concentrate formulated for the production of controlled low strength material (CLSM), more commonly known as flowable fill or flow fill. 3 oz of AERFLOW per cubic yard of finished concrete will increase the slump of the initial mix from 1.5 inches to 7-9 inches. Yields can be increased by 20-25%.

Transport/Mining Materials

ARX-Transport™ is a synthetic foam liquid concentrate engineered to produce a pre-formed foam to transport solid materials such as mine tailings, crusher fines, or sand, either through a pipeline or for large void fill. Using foam technology as a transport medium dramatically reduces the amount of water needed to move the materials compared to traditional methods, reducing dewatering.

ARX-Transport™ is a synthetic foam liquid concentrate engineered to produce a pre-formed foam to transport solid materials such as mine tailings, crusher fines, or sand, either through a pipeline or for large void fill. Using foam technology as a transport medium dramatically reduces the amount of water needed to move the materials compared to traditional methods, reducing dewatering.

Product Guide

Product Guide